Comprehensive Customization and Design Engineering Services

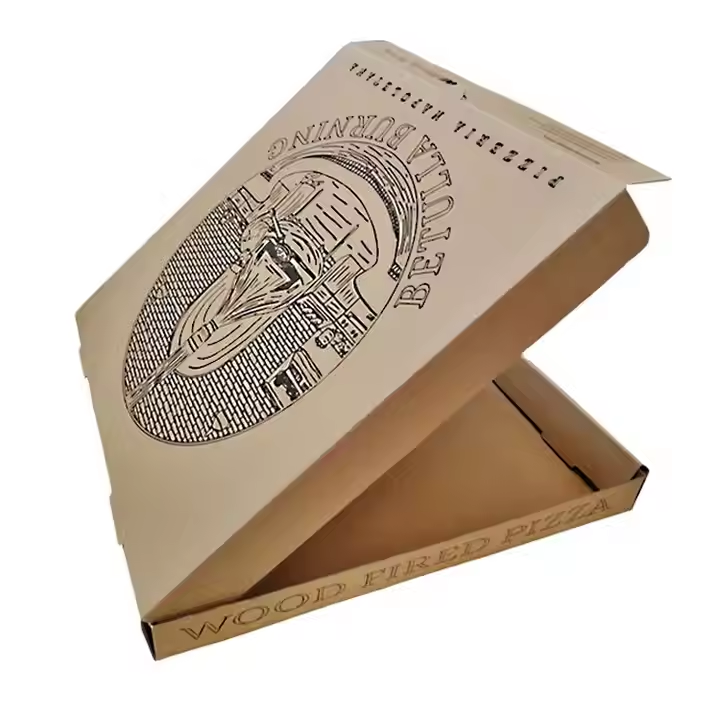

Professional corrugated box suppliers offer extensive customization capabilities that transform basic packaging concepts into optimized solutions perfectly matched to specific product requirements and business objectives. Design engineering teams work closely with clients to analyze product characteristics, shipping methods, storage conditions, and end-user preferences to develop packaging specifications that maximize protection while minimizing costs. Computer-aided design software creates detailed technical drawings and 3D models that visualize proposed solutions before production begins, allowing modifications and improvements during the development phase rather than after expensive tooling investments. Structural engineers calculate load-bearing requirements, stacking strength, and compression resistance based on warehouse conditions, transportation modes, and distribution network characteristics. This analytical approach ensures boxes maintain integrity throughout the entire supply chain from manufacturing facility to final customer delivery. Packaging optimization studies examine material usage efficiency, identifying opportunities to reduce corrugated board consumption without compromising protective capabilities. Right-sizing initiatives eliminate excess packaging volume that increases shipping costs and environmental impact while ensuring adequate cushioning and structural support. Custom insert designs, partition systems, and protective elements shield fragile components, prevent movement during transit, and organize multiple items within single containers. Printing customization encompasses everything from simple text and logos to complex multi-color graphics incorporating photographs, gradients, and special effects. Brand consistency guidelines ensure packaging aligns with corporate identity standards and marketing objectives across all product lines and promotional campaigns. Variable data printing capabilities enable serialization, batch coding, and personalization features that support inventory tracking, quality control, and customer engagement initiatives. Prototype development services create physical samples for testing, approval, and market research purposes before committing to large production runs. Iterative design refinement incorporates feedback from focus groups, distribution partners, and internal stakeholders to optimize functionality, appearance, and cost-effectiveness. Regulatory compliance consulting addresses industry-specific requirements including food safety standards, pharmaceutical regulations, hazardous material classifications, and international shipping documentation needs.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY