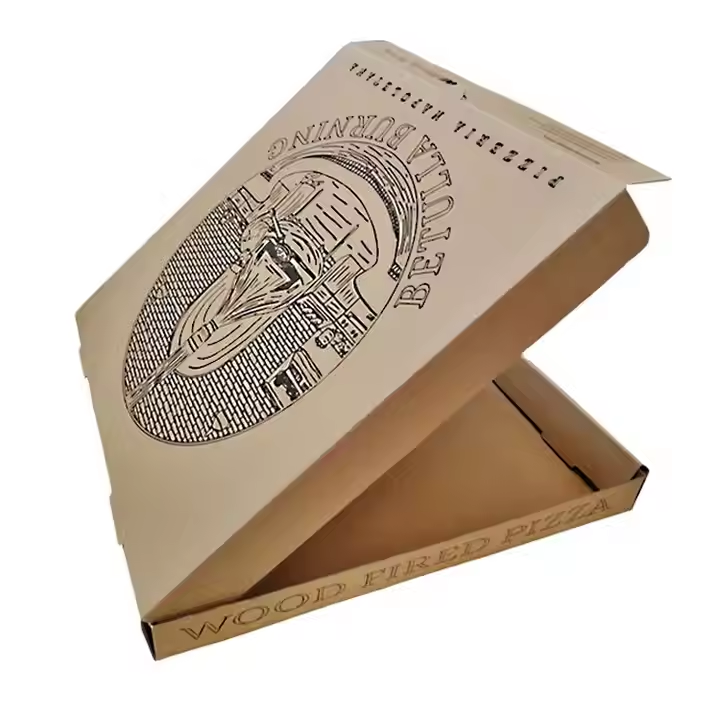

paper for packaging box

Paper for packaging box represents a fundamental component in modern packaging solutions, serving as the primary material that forms the structural foundation of countless shipping and retail containers worldwide. This specialized paper material is engineered specifically to meet the demanding requirements of protective packaging, combining strength, versatility, and cost-effectiveness in a single solution. The paper for packaging box typically consists of multiple layers of recycled and virgin fibers that are bonded together through advanced manufacturing processes, creating a robust yet lightweight material that can withstand various stresses during transportation and storage. The manufacturing process involves careful selection of fiber sources, precise moisture control, and specialized coating applications that enhance the paper's barrier properties and printability. Modern paper for packaging box incorporates technological innovations such as wet-strength additives, which maintain structural integrity even when exposed to humidity, and surface treatments that improve ink adhesion for high-quality printing applications. The material's composition can be customized to meet specific performance requirements, with variations in thickness, density, and surface characteristics tailored to different packaging applications. Environmental considerations play a crucial role in the development of paper for packaging box, with manufacturers increasingly focusing on sustainable sourcing practices and recyclability features. The paper's ability to be recycled multiple times without significant degradation makes it an environmentally responsible choice for businesses seeking to reduce their ecological footprint. Quality control measures ensure consistent performance characteristics, including burst strength, edge crush strength, and surface smoothness, which are critical factors in determining the paper's suitability for various packaging applications. The versatility of paper for packaging box extends beyond basic protection, encompassing branding opportunities through high-quality printing capabilities and structural design flexibility that accommodates diverse product shapes and sizes.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY