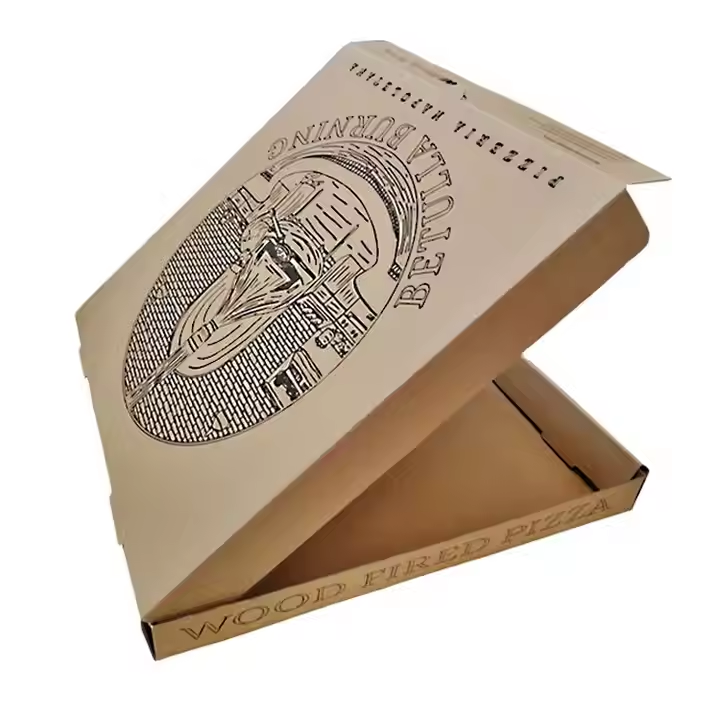

corrugated bins

Corrugated bins represent a revolutionary storage and transportation solution that combines durability, versatility, and environmental responsibility. These innovative containers utilize corrugated cardboard construction, featuring multiple layers of fluted paper that create exceptional strength while maintaining lightweight properties. The primary function of corrugated bins centers on providing secure storage for various products across multiple industries, from automotive parts to agricultural produce. Their technological features include customizable sizing options, moisture-resistant coatings, and reinforced corner construction that prevents structural failure during handling. The corrugated design incorporates air pockets between layers, creating natural insulation properties that protect contents from temperature fluctuations. These bins excel in warehouse operations, retail environments, and distribution centers where space efficiency matters most. Manufacturing processes employ advanced adhesive technologies that bond layers without compromising recyclability, ensuring corrugated bins maintain their eco-friendly profile throughout their lifecycle. Applications span across sectors including electronics packaging, food service distribution, pharmaceutical storage, and textile organization. The modular design allows stacking capabilities up to specific weight limits, maximizing vertical storage space in facilities with height constraints. Surface treatments can include water-resistant barriers, antimicrobial coatings, and custom printing for branding purposes. Corrugated bins feature fold-flat construction for efficient shipping and storage when not in use, reducing logistics costs significantly. Their assembly requires no additional tools or hardware, enabling quick deployment in time-sensitive operations. Weight capacity varies based on construction specifications, with heavy-duty versions supporting substantial loads while standard models handle lighter applications effectively. The corrugated structure provides excellent shock absorption, protecting fragile items during transport and handling operations.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY